Trevista CI Dome

AI-based complex surface inspection

Trevista CI Dome is a hardware and software-based imaging and inspection solution that leverages the power of Vision Pro software to analyze generated images.

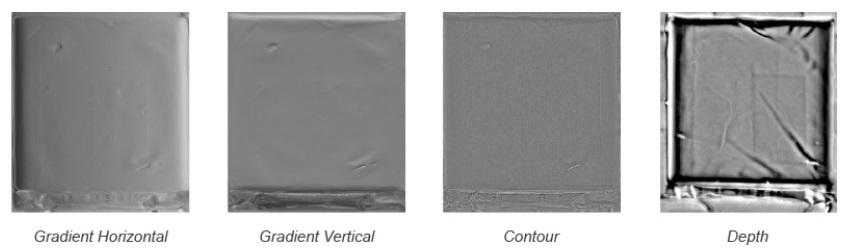

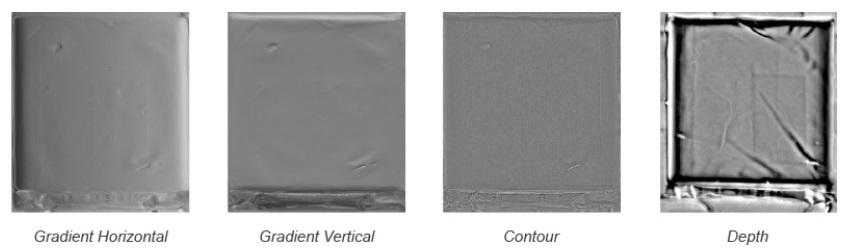

The Trevista vision tool built into VisionPro uses patented “shape from shading” technology to quickly compose high-quality topographic images.

It uses integrated AI-based vision tools to analyze surface defects and differentiate small cosmetic defects from critical defects.

Trevista CI Dome improves inspection processes for parts with glossy or matte surfaces.

BENEFITS:

- Suppression of glare and detection of defects in shiny parts such as metal or ceramic. Absorbs oil / coolant stains on metal parts.

- Detecting defects on low-contrast black-on-black surfaces such as plastic.

- The quality of 3D methods combined with the speed of 2D image processing.

- Analysis both static and in motion.

- Capture 4 images with different lighting that can be processed separately.

INTEGRATION WITH COGNEX VISIONPRO SOFTWARE

- Quickly acquire camera and light controller settings within VisionPro using the built-in Trevista Acquisition Wizard.

- Generate high-quality topographic images using the built-in Trevista tool to calculate shape from image shading.

- Assess defect severity using Trevista composite images with integrated AI-based tools for defect detection and classification.

- Create machine vision inspection applications using Cognex vision software.

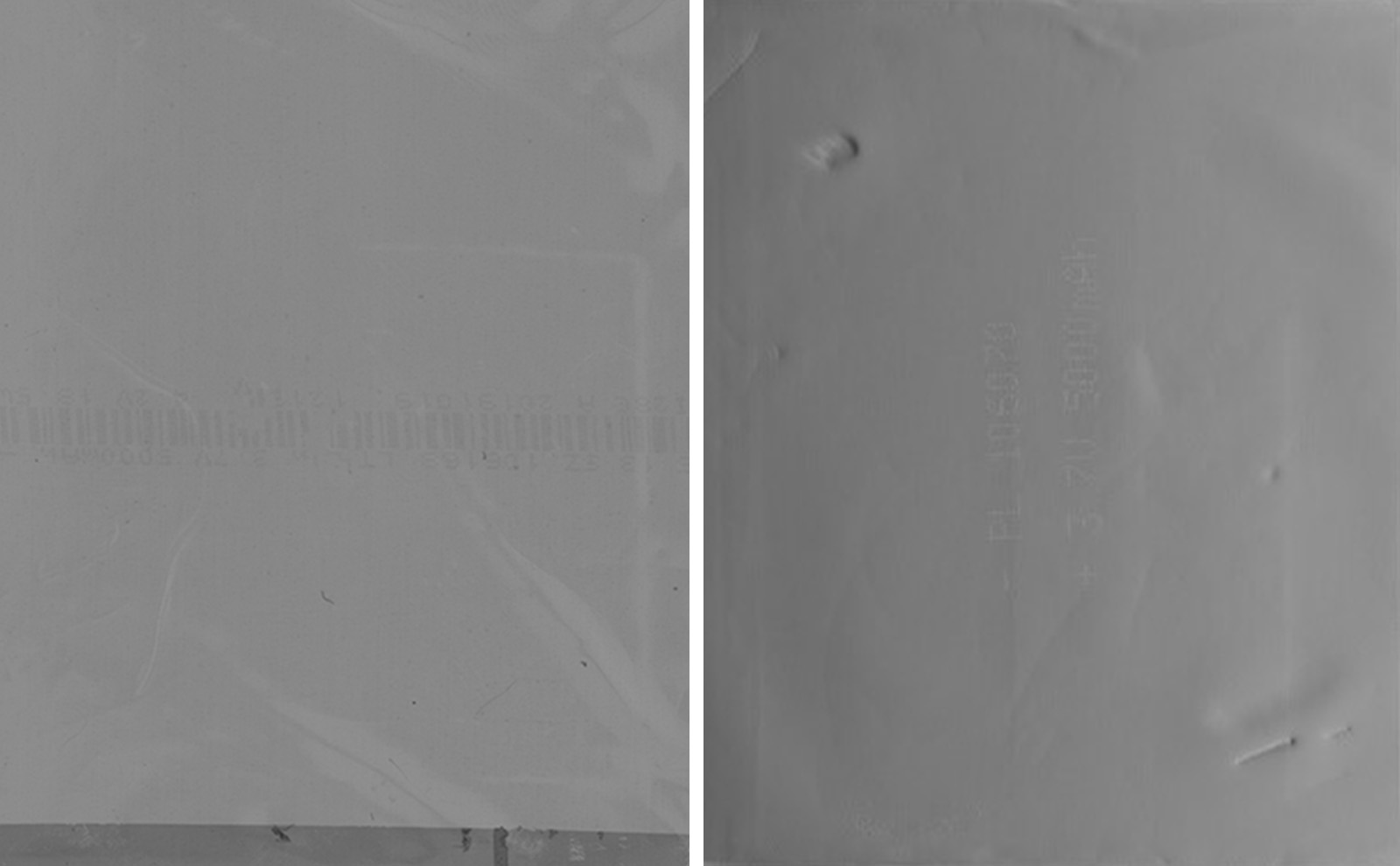

Trevista CI Dome detects subtle defects on reflective and matte surfaces using “shape from shading” technology. Trevista CI Dome is ideal for inspection applications of shiny or matte parts with tight tolerance ranges, such as electric vehicle (EV) batteries and assemblies of PCBs.

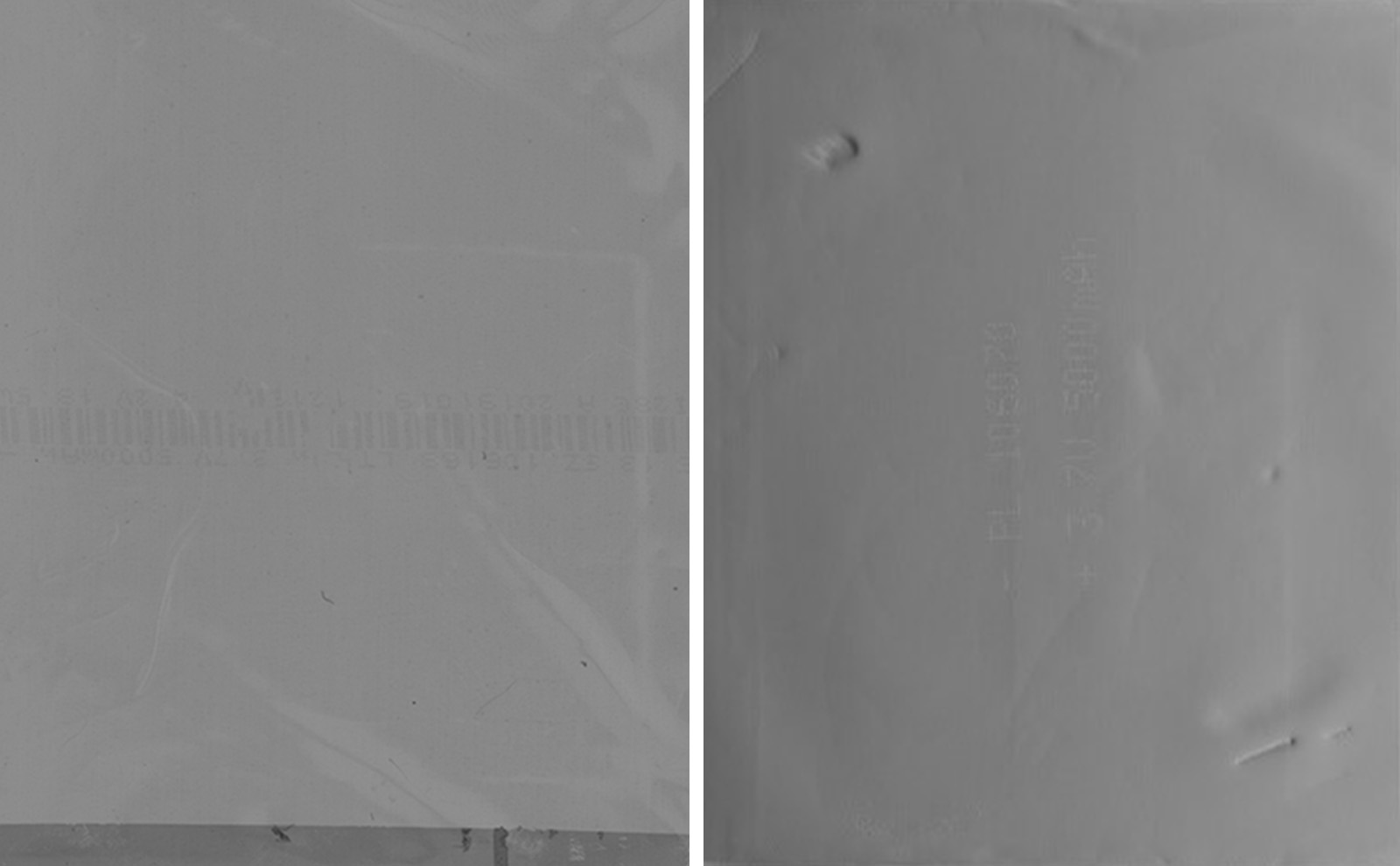

Electric vehicle battery inspection.

Identify surface defects in batteries and classify defects as critical or cosmetic.

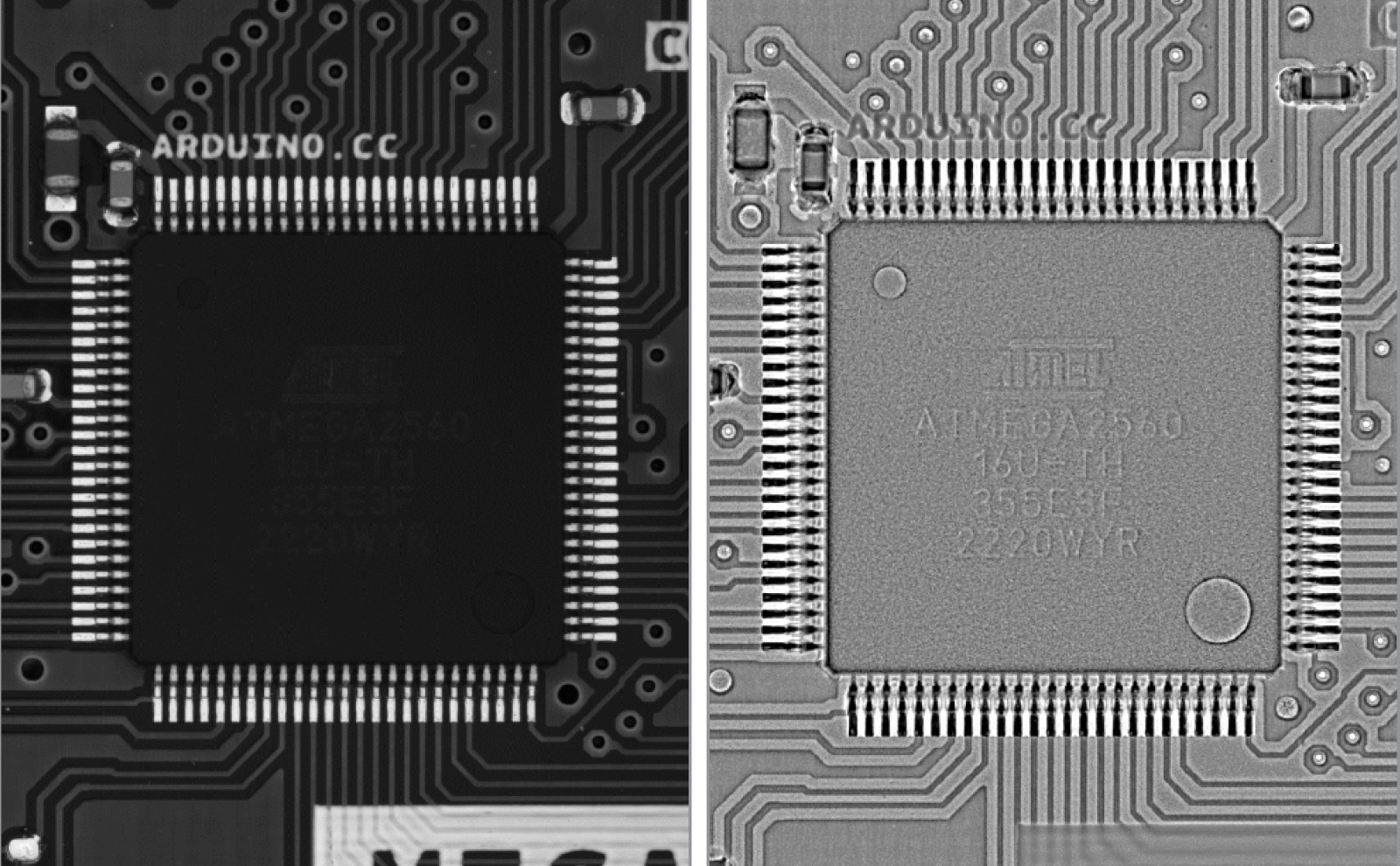

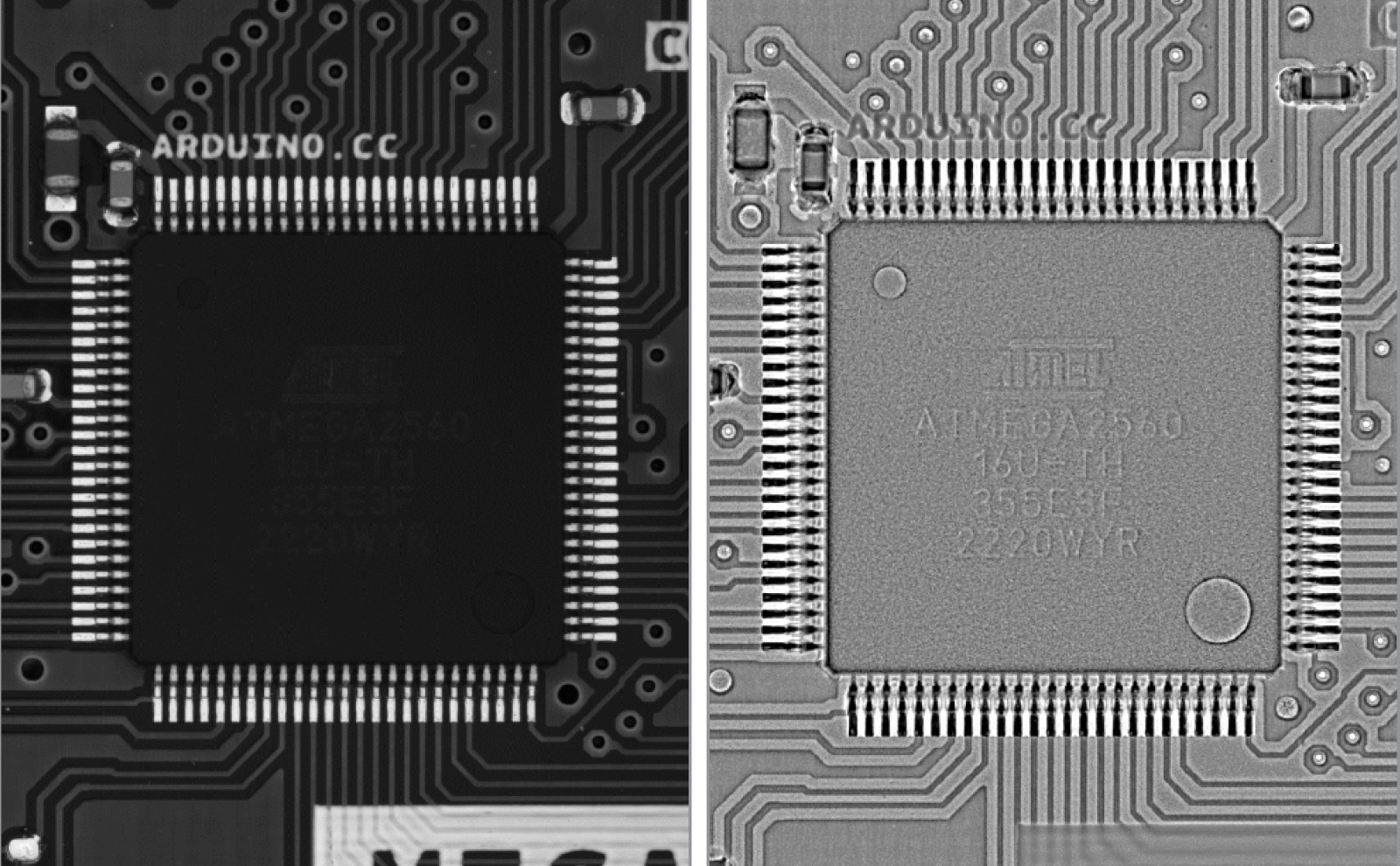

PCB inspection

Check the correct orientation of IC chips mounted on printed circuit boards (PCBs).

Documentation

Technical documentation