Machine vision solutions for the automotive industry

The automotive industry is facing increasingly complex challenges, such as the need to adapt quickly to new technologies and regulations, and the pressure of a more demanding consumer. To remain competitive, it is crucial to incorporate these changes at the speed required by the environment. In this context, machine vision solutions emerge as essential tools to ensure quality, efficiency and precision in vehicle manufacturing.

Below, we explore the most outstanding applications:

1. Presence and absence of components

Verifying the presence and absence of components is essential in automotive manufacturing. Machine vision allows this task to be performed with unmatched accuracy and speed, ensuring that each part is in its correct place. This technology minimizes human error and guarantees assembly integrity, contributing to the production of safe and reliable vehicles.

2. Surface inspection

This is a crucial application for detecting defects such as scratches, dents or irregularities in automotive components. Machine vision cameras, equipped with image analysis algorithms, can identify and classify these defects in real time. This not only improves the quality of the final product, but also reduces costs associated with rework and scrap.

3. Measuring sheet thickness

It is a critical parameter in vehicle manufacturing, as it affects both the safety and performance of the car. Machine vision can measure sheet metal thickness with high accuracy using laser scanning and 3D image analysis technologies. This ensures that all parts meet the required specifications while maintaining quality standards.

4. Industrial traceability on complex materials or codes

It is essential for managing the supply chain and ensuring product quality. Machine vision can read and record complex codes on various materials, such as metals and plastics, providing detailed traceability of each component throughout the manufacturing process. This makes it easier to manage inventories and quickly identify any problems in production.

5. OCR reading on various materials

OCR (Optical Character Recognition) reading is a vital automotive application for identifying and recording information on various materials, including tires, chassis and crankshafts. Machine vision systems equipped with OCR capabilities can interpret characters on complex surfaces, ensuring the correct identification and traceability of each part.

6. Inspections on electronic components

The verification of electronic components, such as clipping and pin alignment, is crucial in the manufacture of vehicle electronics. Machine vision allows detailed inspections of these components, ensuring their correct installation and operation. This is especially important in the production of vehicle safety and control systems.

7. Tire Inspection and Depalletizing

Vision systems can identify and classify tires, facilitating automated depalletizing. This automation improves process efficiency and reduces the risk of tire damage, ensuring that only parts in perfect condition are used in production.

8. LED ignition control

This solution is essential for vehicle lighting and signaling systems, which must function perfectly for road safety.

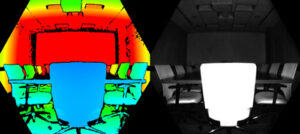

9. Dimensional and volume control

Dimensional and volume control of parts and components uses 2D and 3D technologies to ensure that parts meet specified tolerances. This is essential for the assembly of components that must fit perfectly.

10. Component positioning

This solution takes care of obtaining precise coordinates for component and part positioning, which is vital for automated and robotic processes. This ensures accurate and efficient assembly, reducing production time and errors.

11. Robot Guidance

This is one of the most advanced applications of machine vision in the automotive industry. These systems can provide real-time information on the position and orientation of parts, allowing robots to perform complex assembly and handling tasks with high precision. This improves the efficiency and flexibility of the production line.

12. Bin Picking Systems

Use machine vision to identify and pick parts from a garbage can autonomously. This technology is essential for the automation of assembly processes, as it allows robots to accurately select and place parts, increasing productivity and reducing the need for human intervention.

13. Glue or weld bead control

This system is crucial to ensure the quality and strength of the joints in vehicles by inspecting these seams in real time, detecting any defects or inconsistencies. This allows immediate corrections to be made and ensures that all joints meet safety and durability standards.

14. Control of silkscreen printing on glass

This application ensures the correct application of patterns and texts on vehicle glass. This is important for both aesthetic and functional reasons, ensuring that the screen prints are legible and well aligned.

15. On-board vision on robots for verification and measurement

This involves measuring and verifying large parts during the assembly process. Robots equipped with vision systems can perform detailed inspections and precise measurements, ensuring that all parts are assembled correctly and meet technical specifications.

16. Electric Vehicle Applications: Battery Inspection

In the context of electric vehicles, battery inspection is a critical application. Batteries must be thoroughly checked to ensure their integrity and performance.

Machine vision can perform detailed inspections to detect defects in battery cells, measure alignment and ensure correct assembly. This is critical to the safety and efficiency of electric vehicles, as any defect in the battery can have serious consequences.

In conclusion, machine vision solutions have revolutionized the automotive sector, offering a wide range of applications that improve quality, efficiency and precision in vehicle manufacturing. From component inspection to robot guidance, machine vision has become an indispensable tool for the industry. As technology continues to advance, we are likely to see even more innovations that will continue to transform the automotive industry, making processes safer, more efficient and more cost-effective.